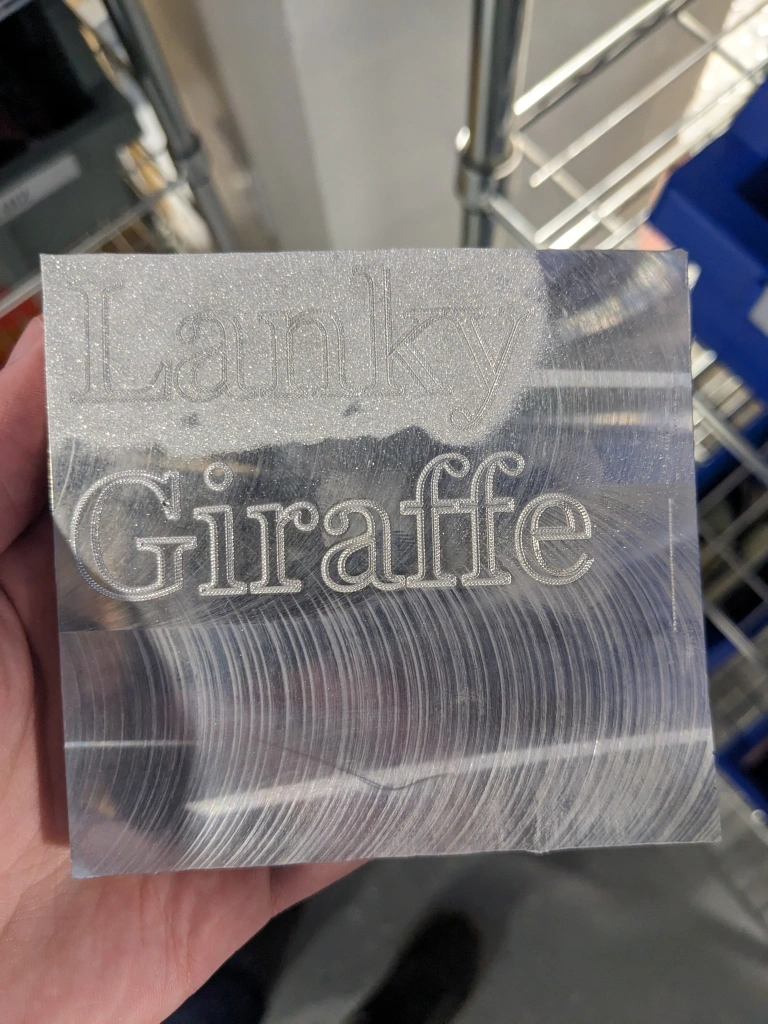

On Monday I tested out the engraving method I will use for the plaque I’m making for Watts Water Technologies. I used a diamond-drag engraving bit in the Tormach to CNC engrave some text (the words “Lanky Giraffe” were provided by Tanzy). The above engraving involved three engraving passes for each character offset 0.01 inches. The text came out very good and I believe I will continue to use this method for all my future engraving. I also was curious to see what the text would look like when sandblasted. The answer is not too good.

Before facing

After facing

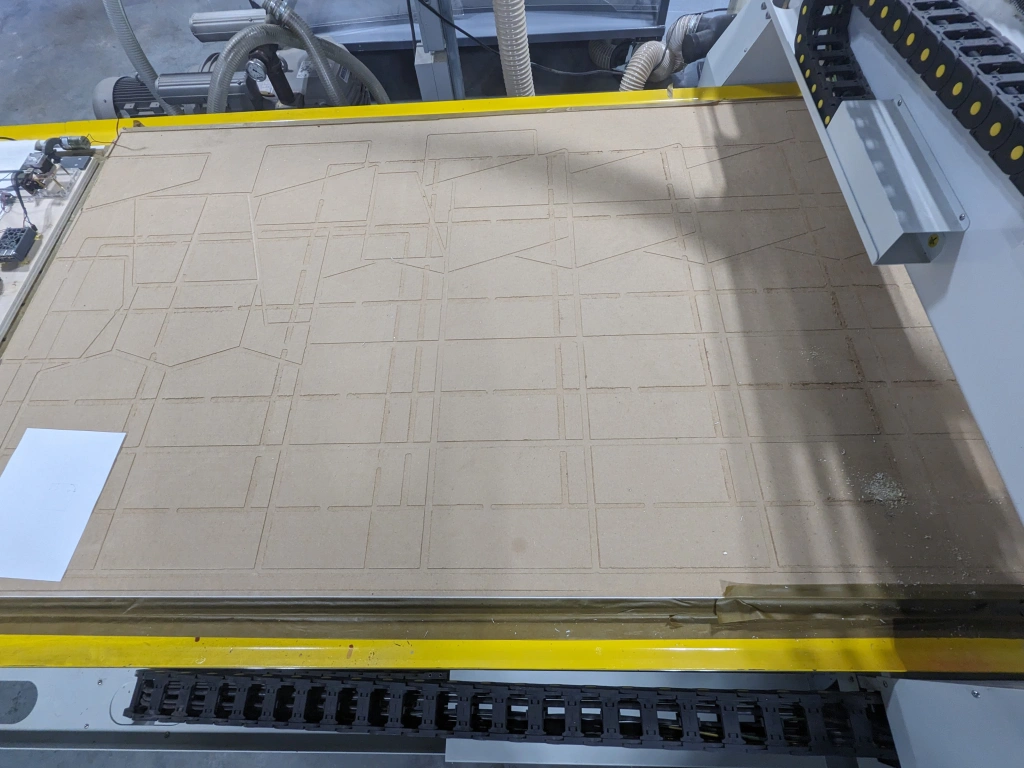

In order to cut the wooden portion of the Watts Gift, I need to use the CNC router. I have had some experience with the machine, but I am definitely not confident with it yet. However, before the router can be used at all this year, the MDF board on it must be flat. It could either be replaced, or it could be faced down so that it’s flat again. I decided to try facing it down, and this involved creating a CNC program to have the router run over the entire board with a 3 inch diameter wood facing bit.

The program did not end up facing the entire board, with ~.25 in of board left over. I didn’t measure or zero the board or machine…. in any precise way, so this was expected. I manually faced the remaining bit by jogging the machine with the spindle active. Once the board was completely flat, I removed all of the old tape and retaped the board with the assistance of Tanzy.

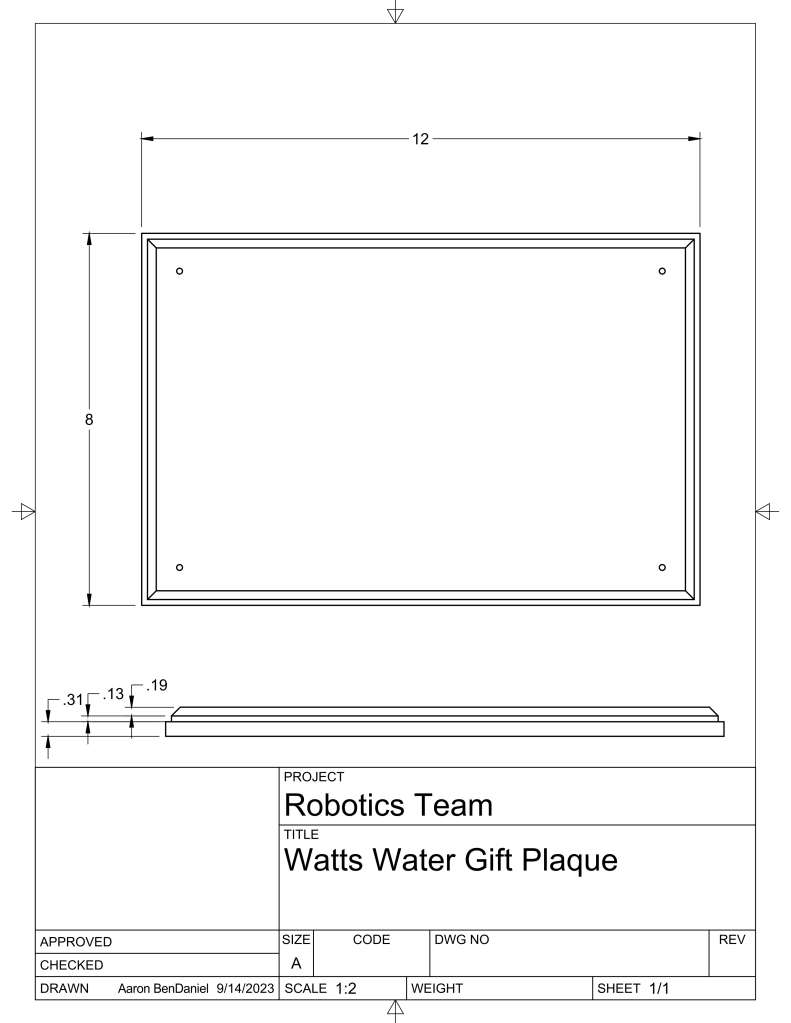

I have written a CAM program to route the wooden part of the Watts Gift, but I haven’t cut it yet (as of Thursday).