This week was a 4-day week, so I got less done this week than I normally would.

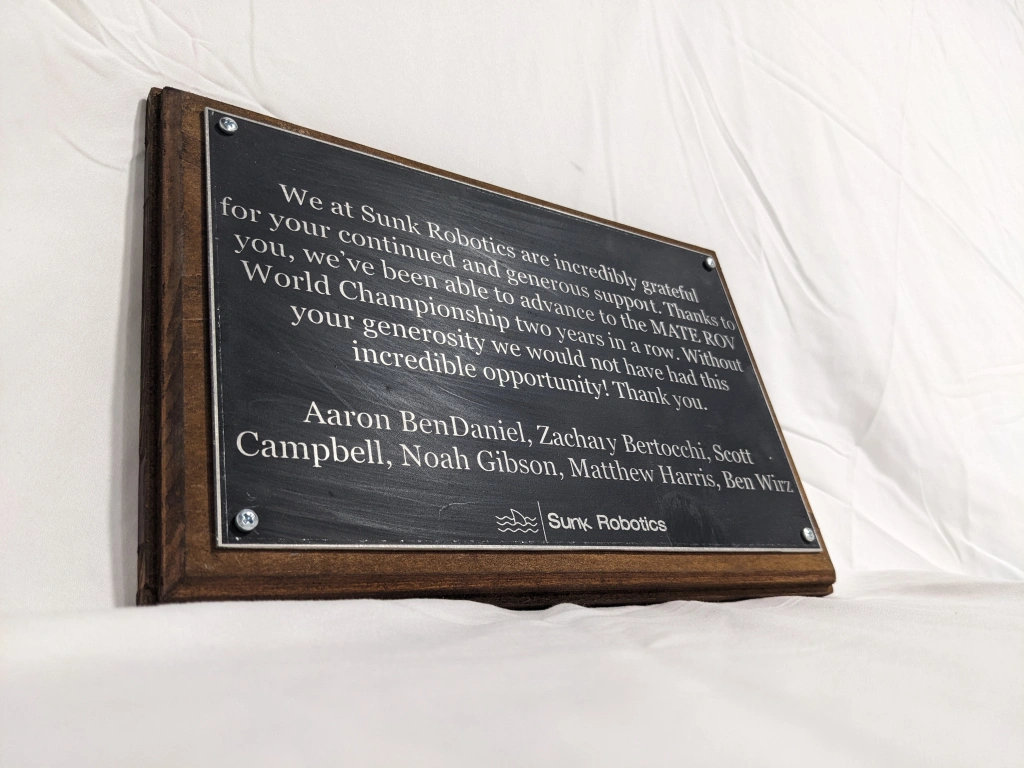

I finally finished the plaque for Watts Water, and it looks pretty good! I’m quite disappointed that my CNC engraved idea didn’t work out. I ended up just spray painting the metal sheet and then laser-engraving the text into it. The upside to this method is that I can do solid shapes and logos, instead of just lines.

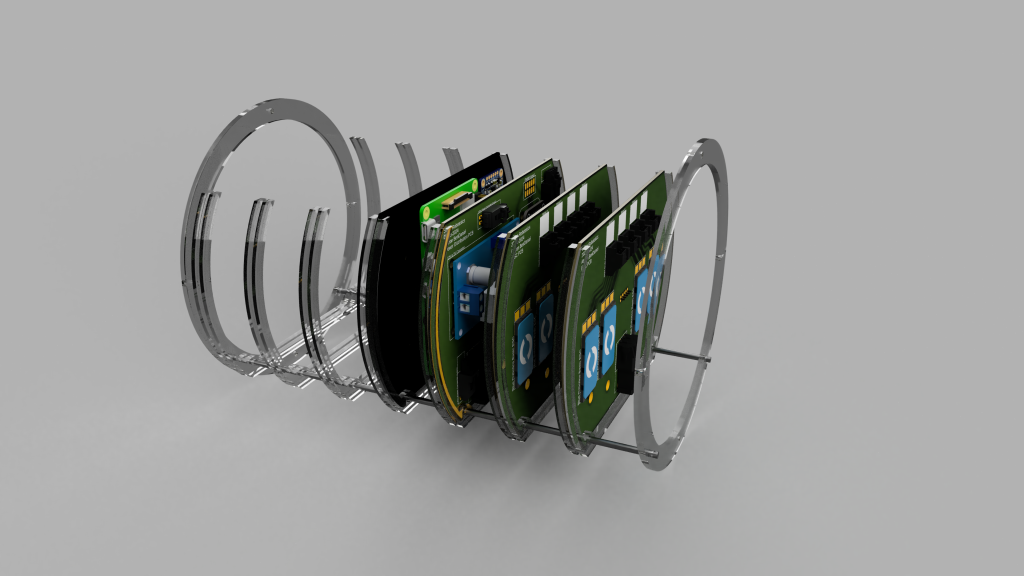

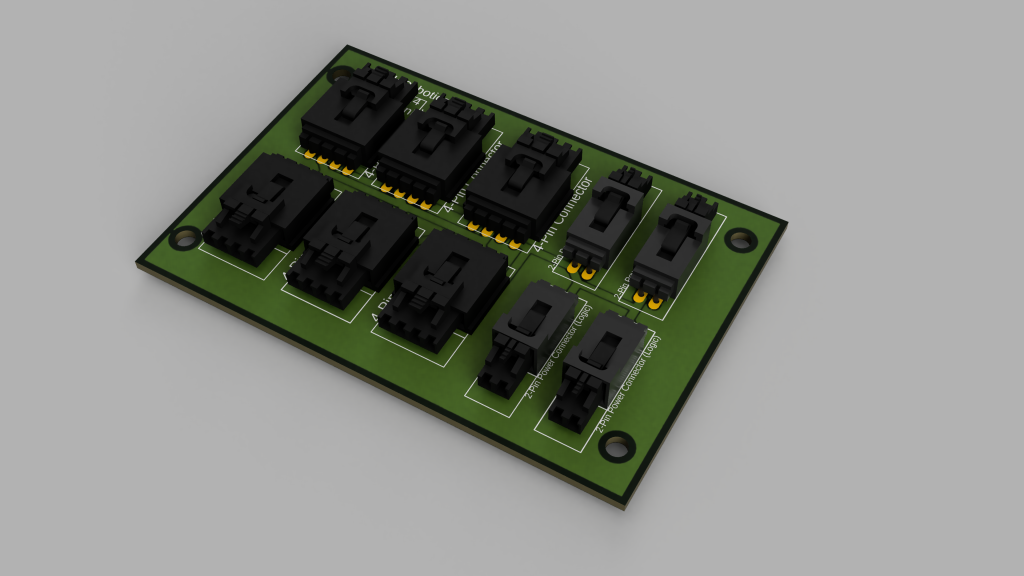

After I finished up the plaque, I got back to work on the new electronics enclosure. Our new design will hopefully be far cleaner, easier to modify, and will also look a lot cooler. Our main tube (6in diameter) will have a frame with a bunch of slots on it, and a bunch of PCBs will go into each slot and be connected together with as few wires as possible. This week I designed two PCBs: the Power Distribution Board, and the I2C & Power Bus Board.

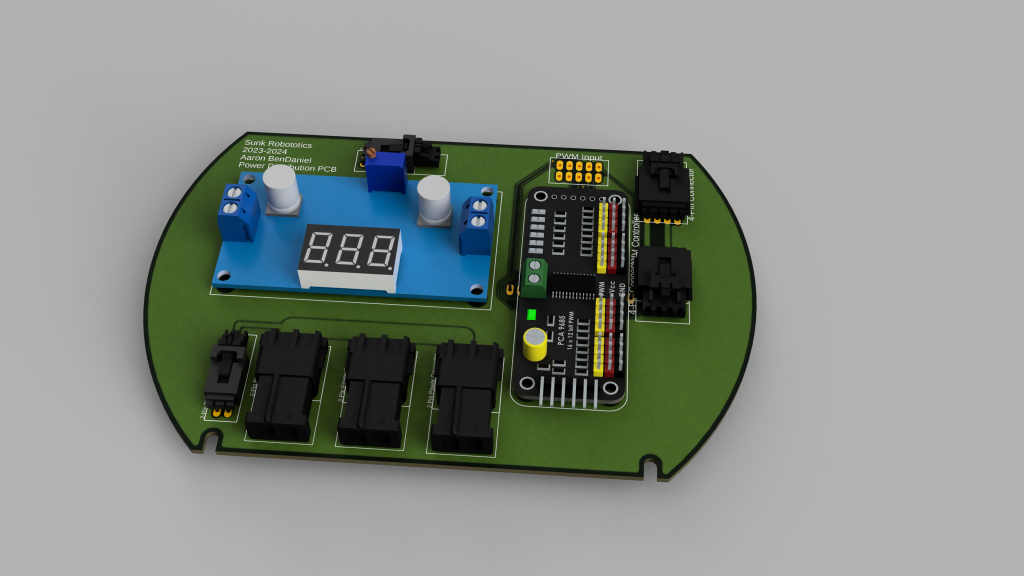

The Power Distribution Board splits the incoming 12V for use in the two ESC Boards, and for the 12V to 5V converter on the PCB. The Power Distribution Board also has the 12 Channel PWM Controller for the ESCs, as it is the closest board to the ESC boards and the extra space.

The I2C & Power Bus Board has a 6-port I2C bus and a 4-port 5V power bus. This board is not full size, and will go on a clear acrylic piece that fill fit into the electronics frame. This acrylic piece will also hold the Raspberry Pi 4B and a 9-axis IMU.

While writing this blog post I thought of a much better way to do the I2C & Power Bus Board, so I’m gonna completely remake it Friday.