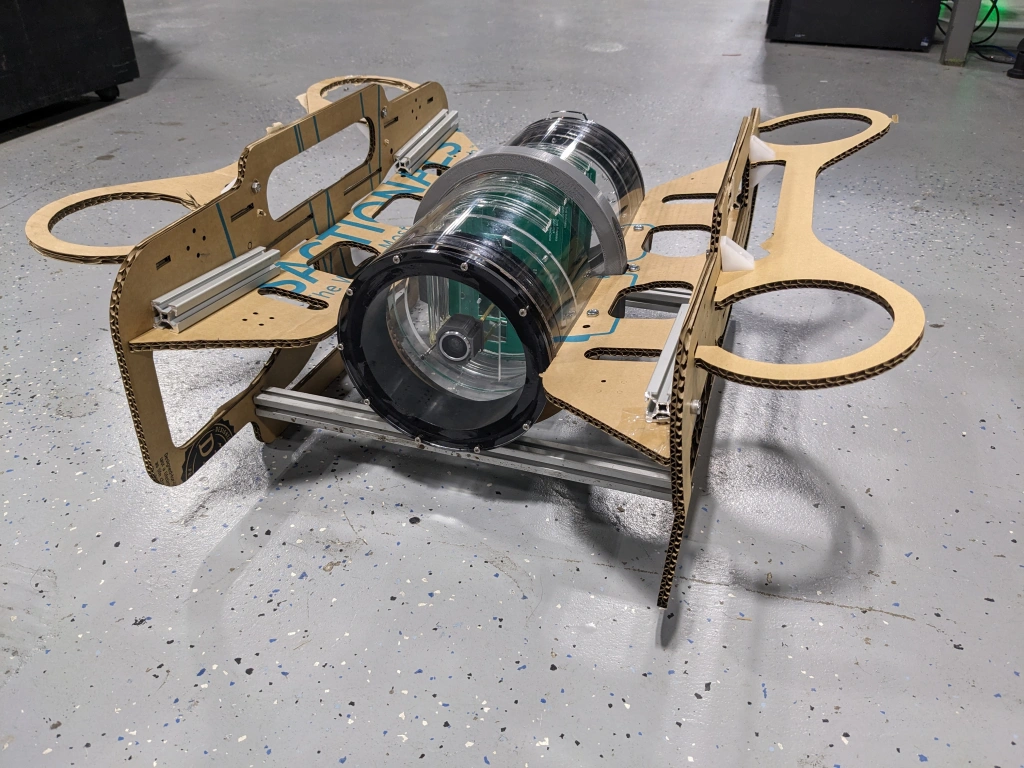

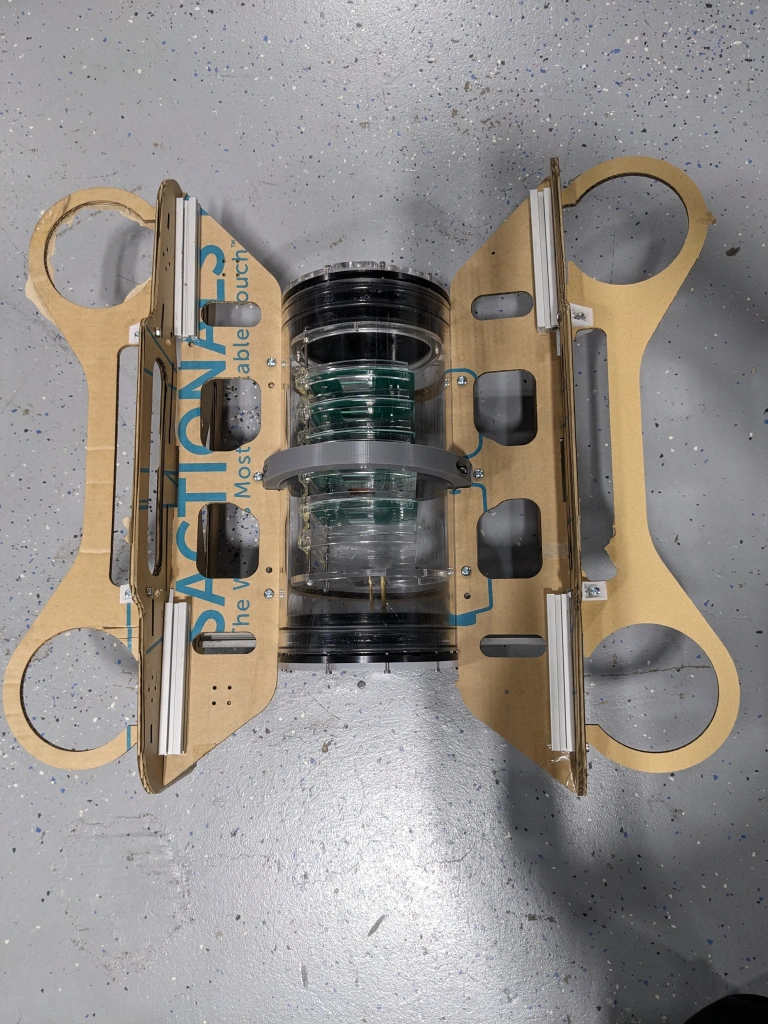

This week I built a cardboard model of JONA ROV. I laser cut all of the parts and cut lengths on 80/20. I had thought that the 80/20 we had came pre-threaded, as the 80/20 on S.T.E.V.E. was threaded, but apparently the stuff I used was not. I tapped the parts of 80/20 that needed screws through them. In the process of assembling the model, I noticed that some holes had not been cut, and I found out that I had forgotten to model them in the 3D model. I also ran out of the screws I’ll use to assemble the frame, so I ordered more of them.

Building a cardboard model of the ROV was definitely a good idea, it reassured me that everything would work the way I wanted, and helped me discover some mistakes in my 3D model. Unfortunately, the interlocking tabs can’t be tested in cardboard, as they’re dependent on the thickness of the material, and cardboard is significantly thicker than the 1/8in aluminum the final frame will be made out of.

Recorded by Ben Wirz

I began cutting the final metal frame out of aluminum with the Water-Jet Cutter. It was fixed just this Monday, and I finally got to learn how to use it! It wasn’t too difficult, as it is similar to many of the other CNC machines I’ve used before such as the Plasma Cutter and CNC Router. The Water-Jet was broken for most (if not all) of last year, and I’d been waiting for an opportunity to use it for a long time. Hopefully, by the end of next week, all of the parts for the frame will be cut and sanded. Ben suggested we get the pieces anodized, but I think we’ll just end up spray-painting them.

I also ordered the rest of the PCBs for the electronics enclosure. The ESC PCB did not have any problems (other than it’s color) so we went ahead and ordered the other PCBs. We decided to go with green in order to stay consistent, although I’m sure the black PCBs we had planned on would have looked better.