This was a short week as we had Tuesday off because of the presidential election.

The main thing I did this week was to continue supervising the Sophomores in the machine shop while they were making their Turner’s Cubes. This took up pretty much all of my time, so I didn’t get to get much work done on my Micromouse.

On Monday, I made some changes to and ordered the Upper Boards from JLC PCB, so they should be arriving sometime next week and I should (hopefully) be able to finish the hardware for my Micromouse.

On Wednesday, I wrote code to turn the on-board Neopixel on the QT-PY into a status indicator. I will use the RGB-LED to indicate the current state of the Micromouse. The color scheme will be:

Green - Done

Blue - Waiting

Yellow - Moving

Red - Failure

| |

I also wrote some code to use the on-board push-button to prompt the Micromouse to continue. I can add a buttonCheckpoint(); line in the code to make the Mouse wait for a button press before continuing.

| |

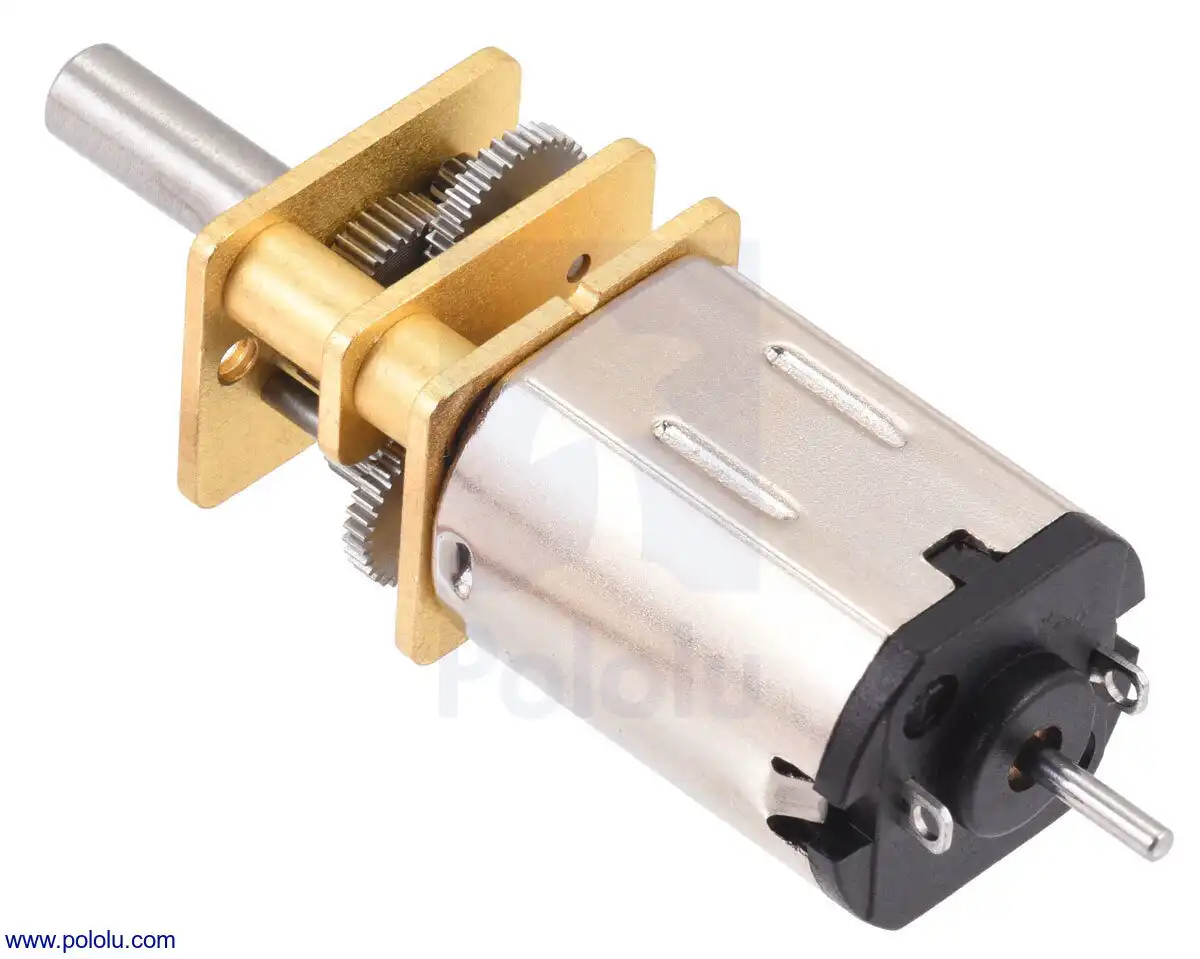

Last week, when I assembled the Lower Board, I switched one of the motors I had for another one that had straighter headers. I did not inspect or test the new motor at all. This was a mistake. Despite being labeled “50:1” the gear ratio on it was actually 75:1. This meant that one wheel took significantly more torque to turn and spun at a slower rate.

On Thursday, I desoldered the mislabeled motor and replaced it with one that I had verified had a 50:1 gear ratio.