This week I spent turning the parts of my Tap Follower.

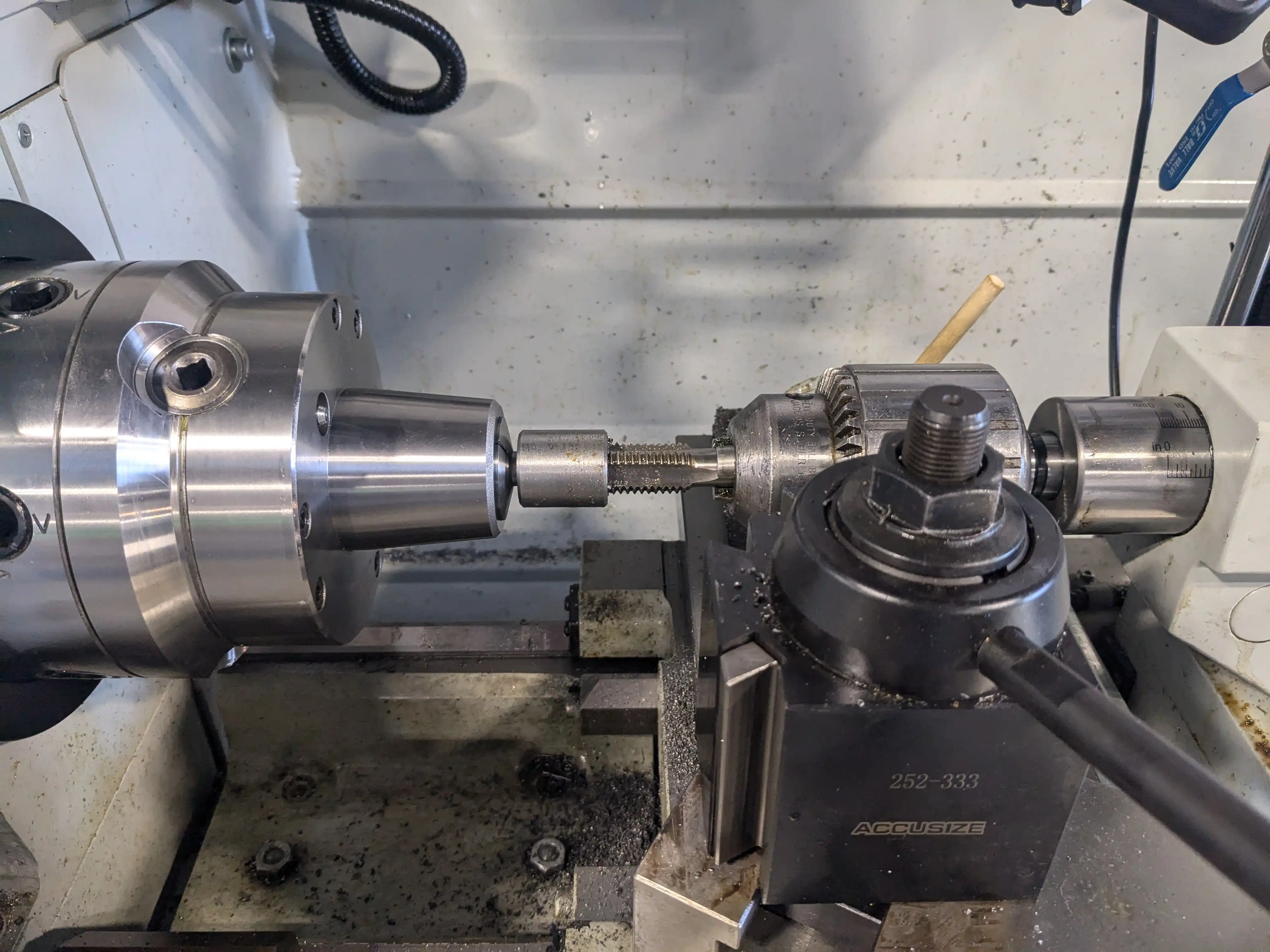

On Monday I finished up threading the holder, which ironically, was the perfect situation for a tap follower.

Once the holder was done, I turned the head, which was interesting because it features a taper that I had to cut with the lathe’s compound.

The head was a pretty simply part and I finished it quite quickly. With the head done, all the main parts of the Tap Follower were complete and I could assemble it.

Along the way, I discovered the most delightful behavior, when pulling a 0.413 inch gauge pin out from the body, it creates a good-enough seal to pull a vacuum and go *pop* when it’s released.

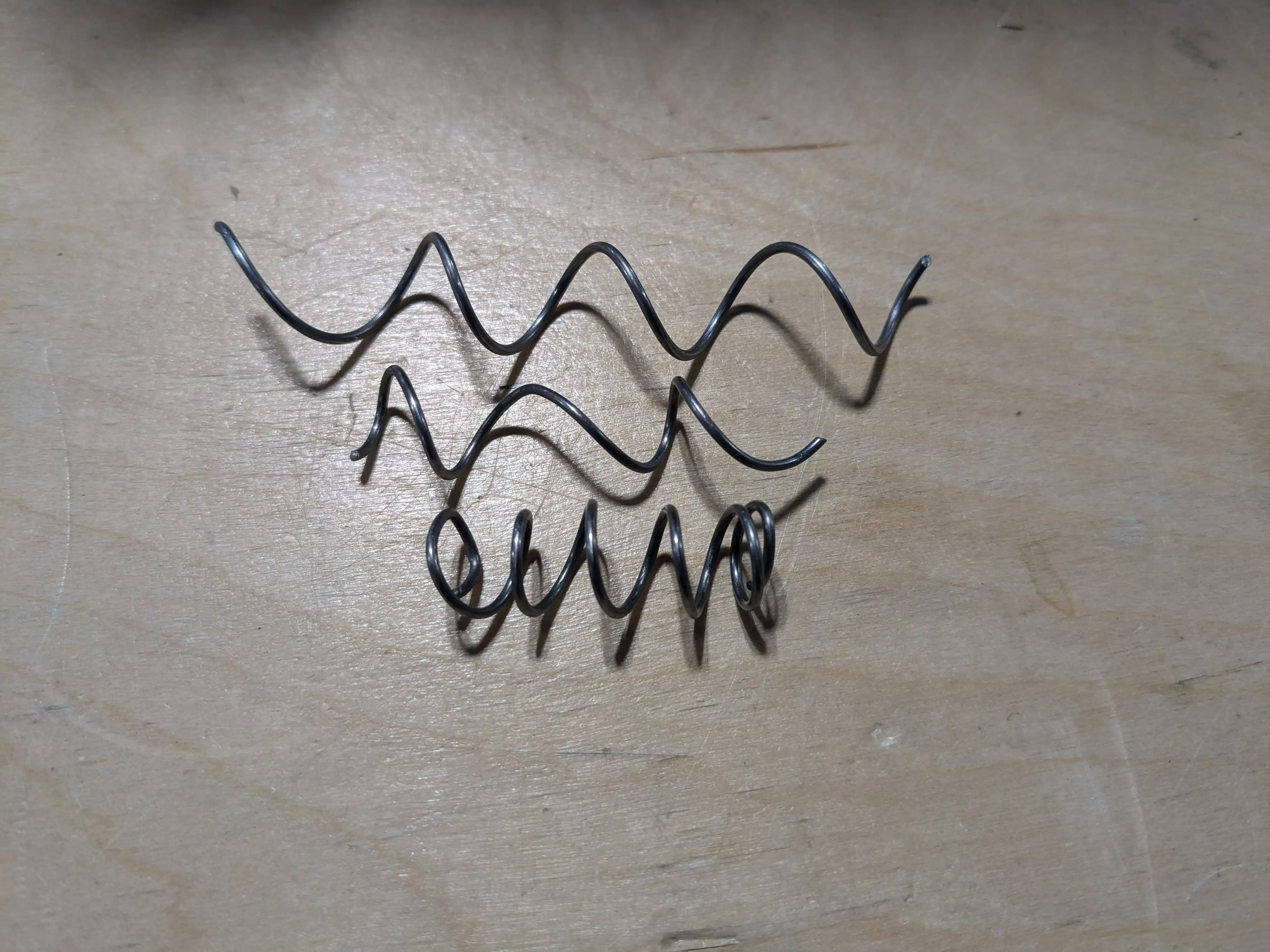

The final part for the Tap Follower is the spring. I had originally intended to wind my own spring, as I had been told that it wasn’t too hard. However, after a couple attempts, I didn’t really get anywhere and gave up. I will be buying a professionally made spring instead.

Despite my failures with winding my own springs, the second one I made worked… sort of. Ben got to try the tap follower out for a single thread before the spring was deformed too much and was rendered unusable. I think the springs I’m making are plastically deforming far too easily, and with springs I buy, I will be able to actually shop around for springs with suitable minimum lengths.

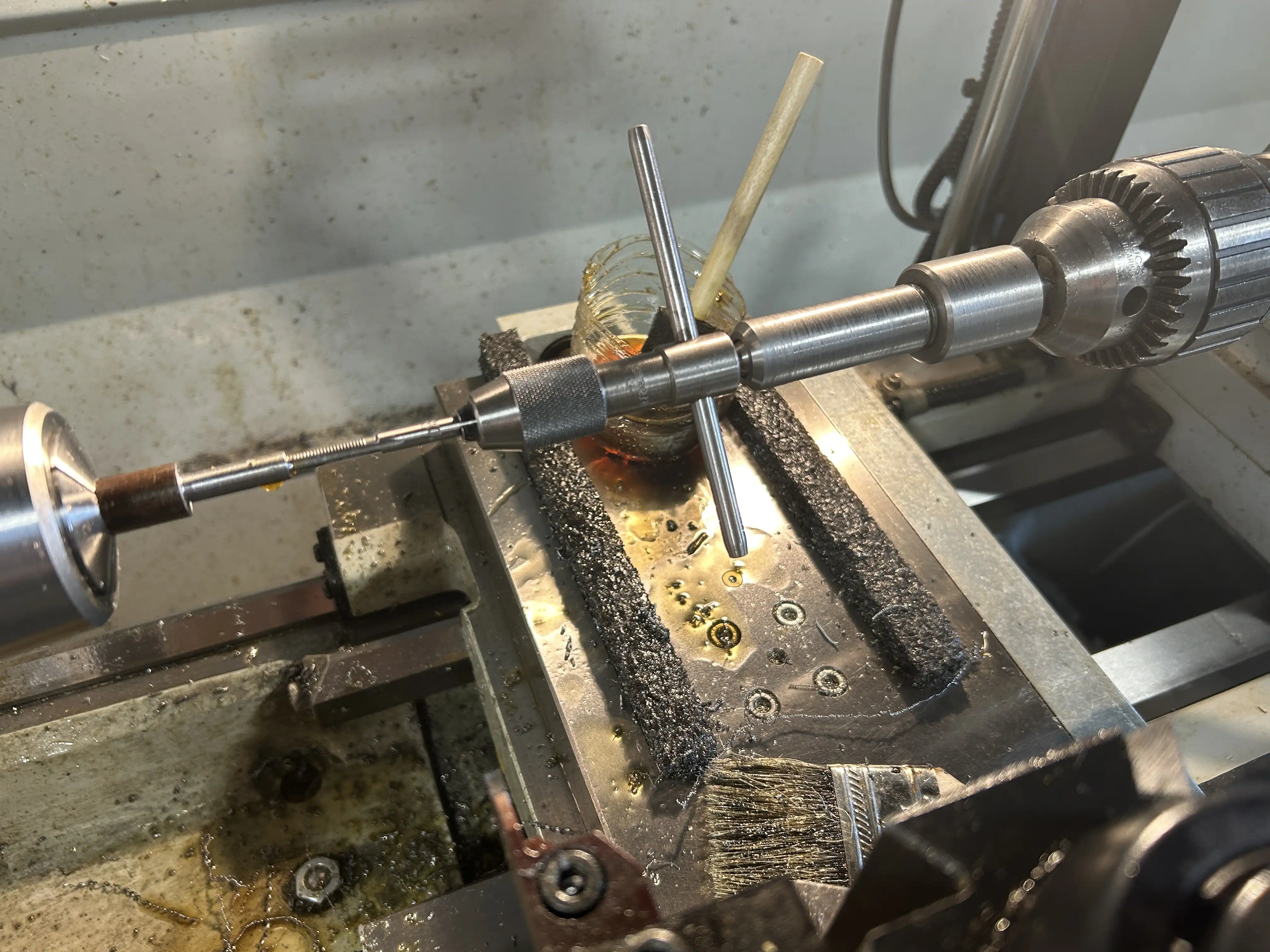

On Thursday, I didn’t have much to do because I needed to wait for my springs to be ordered, so I reorganized all of our resin printing stuff (while storing all the new stuff that arrived). The area underneath the resin printers is much cleaner now. I also spent quite a bit of time helping Tim thread some steel rods, and curiously, we were unable to. The die simply wouldn’t catch and I nor Mr. L could figure out why. I will probably assist Tim with cutting the threads on the lathe.

I also decided to start work on a hopefully short project from Mr. L to make some covers for the South Bend lathe’s ways. We’re going to buy some fabric bellows covers and I need to design a way to mount them on the lathe.