Two or three weeks ago, the main high-pressure water line for the water jet that connected the pump to the nozzle ruptured, with a jet of water shooting out of it when in use. This was, obviously, bad, and needed to be fixed as soon as possible. Mr. Christy ordered the replacement part soon after, but it only arrived just this week.

As the person most experienced with the waterjet, and with my general interest in the maintenance procedures of our machines, I offered to help fix the waterjet.

Mr. Christy and I spent most of Tuesday and Wednesday attempting to install the replacement part. We only half succeeded. The ultra-high-pressure water requires extremely delicate seals in order to remain leak-free, and we were unable to stop one end of the line from leaking. Our repair technician for the waterjet recommended replacing the block that it connects to, as all ultra-high-pressure parts are subject to high wear and are considered consumable. We will have to wait some additional time for the extra replacement part to arrive.

The other main thing I did this week was getting to work on redoing Sunk Robotics’ website. I had originally planned to selfhost a Wordpress instance using a server in the Shop, but gave up after failing to find a way to tunnel out of the school’s locked-down network (for free) without port forwarding and decided to use Hugo.

However, after speaking with Mrs. Miller, the Programming & Web Development teacher at MVTHS, I learned that the Programming shop already pays for a service called Bluehost, which supports Wordpress hosting. Mrs. Miller offered to host Sunk Robotics’ website, so I set that up this week. Unfortunately, my work is not done, as connecting the domain sunkrobotics.com to the wordpress instance hosted by bluehost requires some additional setup that I was not able to do this week.

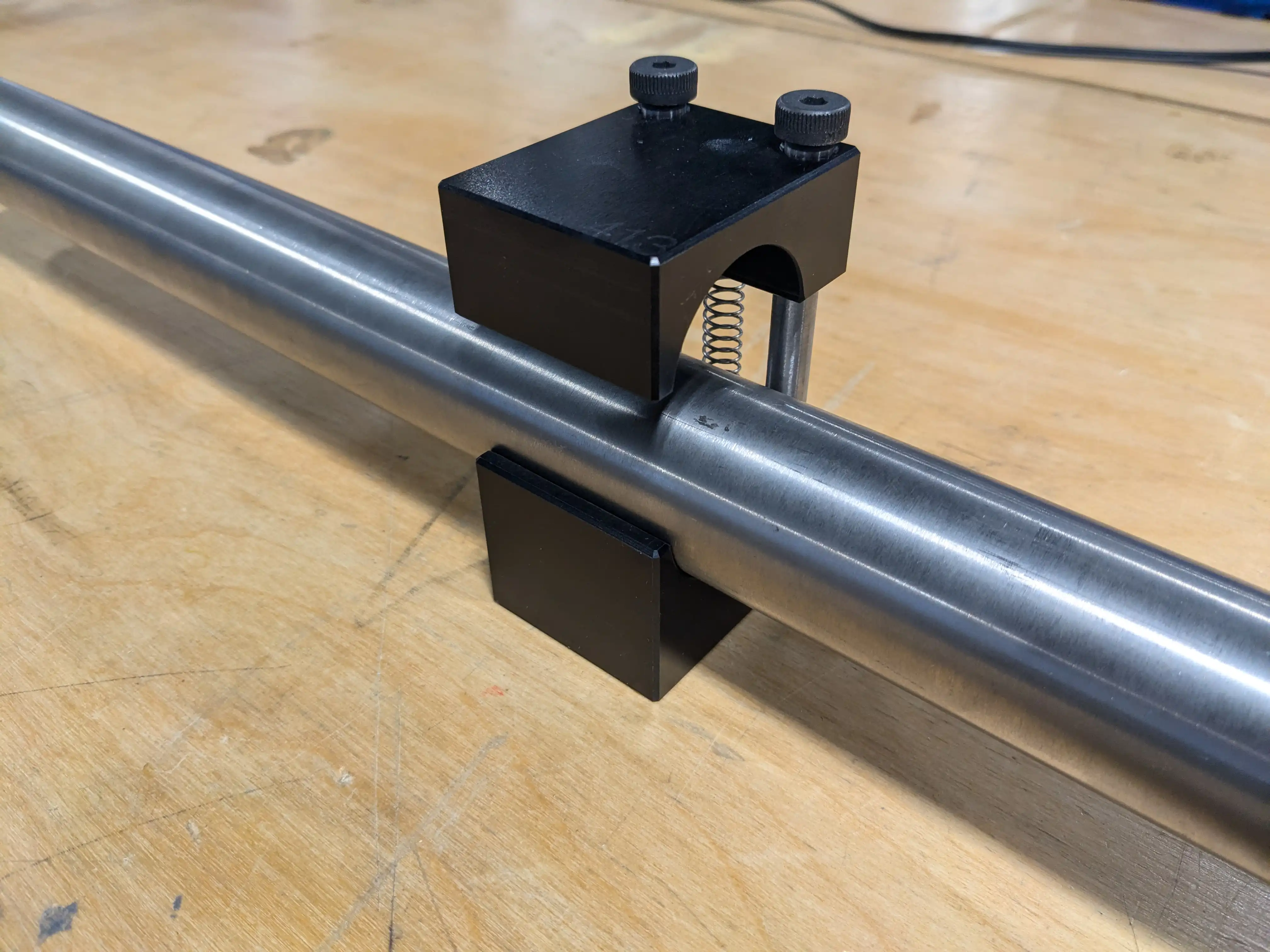

I also started (yet another) machine shop project. Metal Fab needs a clamp to hold some metal tubing, but the one they currently have (and gave to me for reference) does not hold the tube square in the clamp, which is needed for the project they’re working on. They asked the Robotics shop to make a second clamp that would hold the tubing centered relative to the sides of the part. I took on the job of making it. I only started it on Wednesday, so I didn’t get much work done, but it looks like I’ll get to use a new type of milling tool, known as a Shearhog, so that will be interesting.

I’m going on a trip to Rutgers University, so I will not be in school on Thursday or Friday, which is why this blog post is early.