Last week, I started working on a project from Metal Fab to make a clamp to hold some bike parts. The unique thing about this project is that it involves milling a pocket that is 3" deep. This is deeper than any of our normal tooling can reach. Luckily, we do have a tool that can reach that far. Mr. L had barely used it, so I had to learned all about it and test it out to see what its limits are.

This tool is known as a “Shearhog” and is a roughing tool specifically for aluminum.

After quite a bit of testing, I got some feeds and speed that appear to work well with the tool. I’ve got it cutting 1.2in^3 of aluminum per minute, which is quite fast. I ended up cutting through two fairly large pieces of stock finding the right settings to use, but I hope we’ll be able to make good use of this tool in the future.

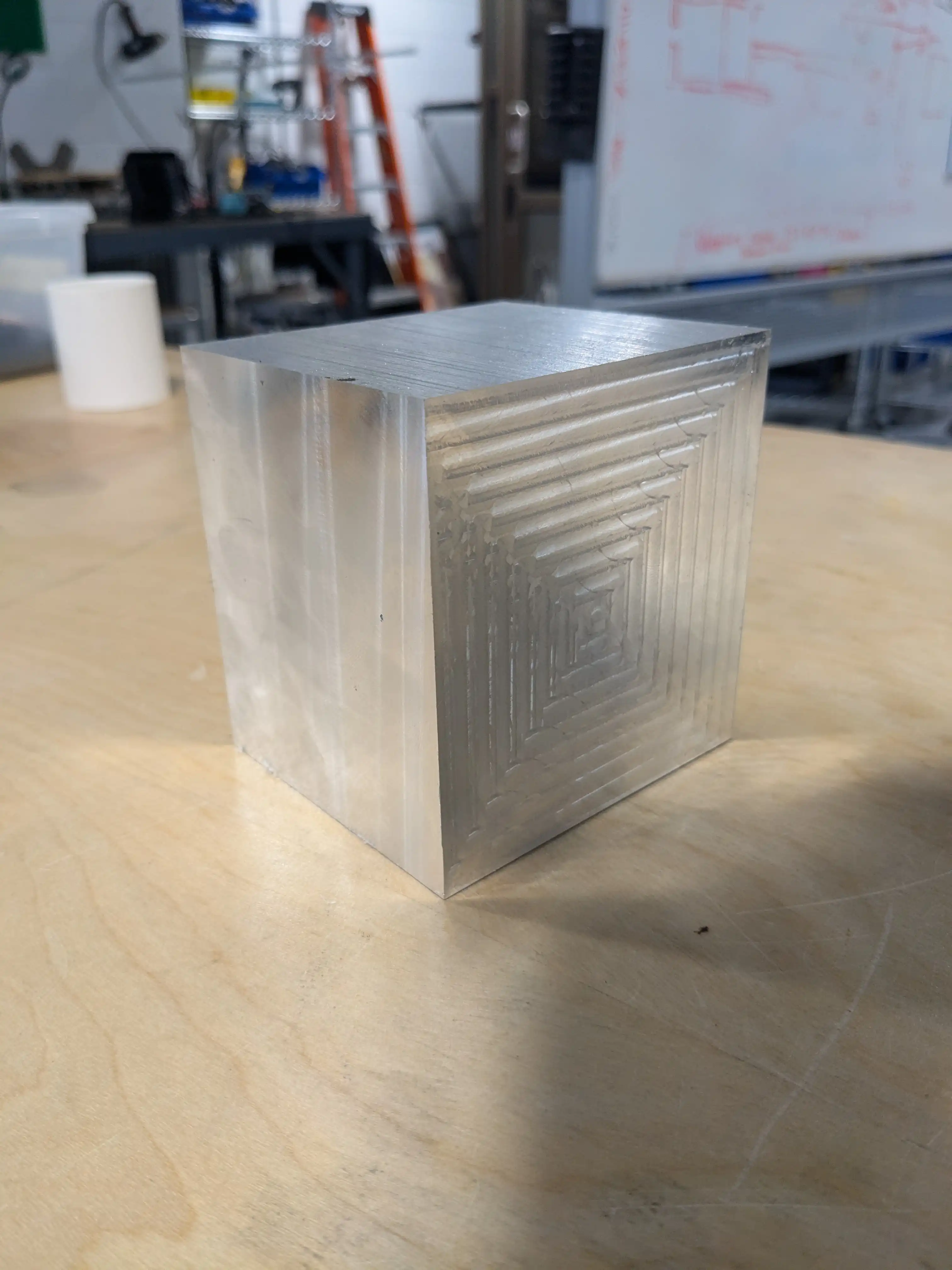

Once I’d learned how to use the Shearhog, I could get started on actually manufacturing the part. I needed to start with facing down the stock to the correct size to get its size in line with what I have in CAM, and to get the sides flat and square.

The shearhog can chew through quite a lot of material and makes a big mess of the Tormach, which I needed to clean up.

I didn’t have time to do all the faces, but so far I’ve faced three of the six sides I’ll need to do.