We had Monday off, so it was a short week.

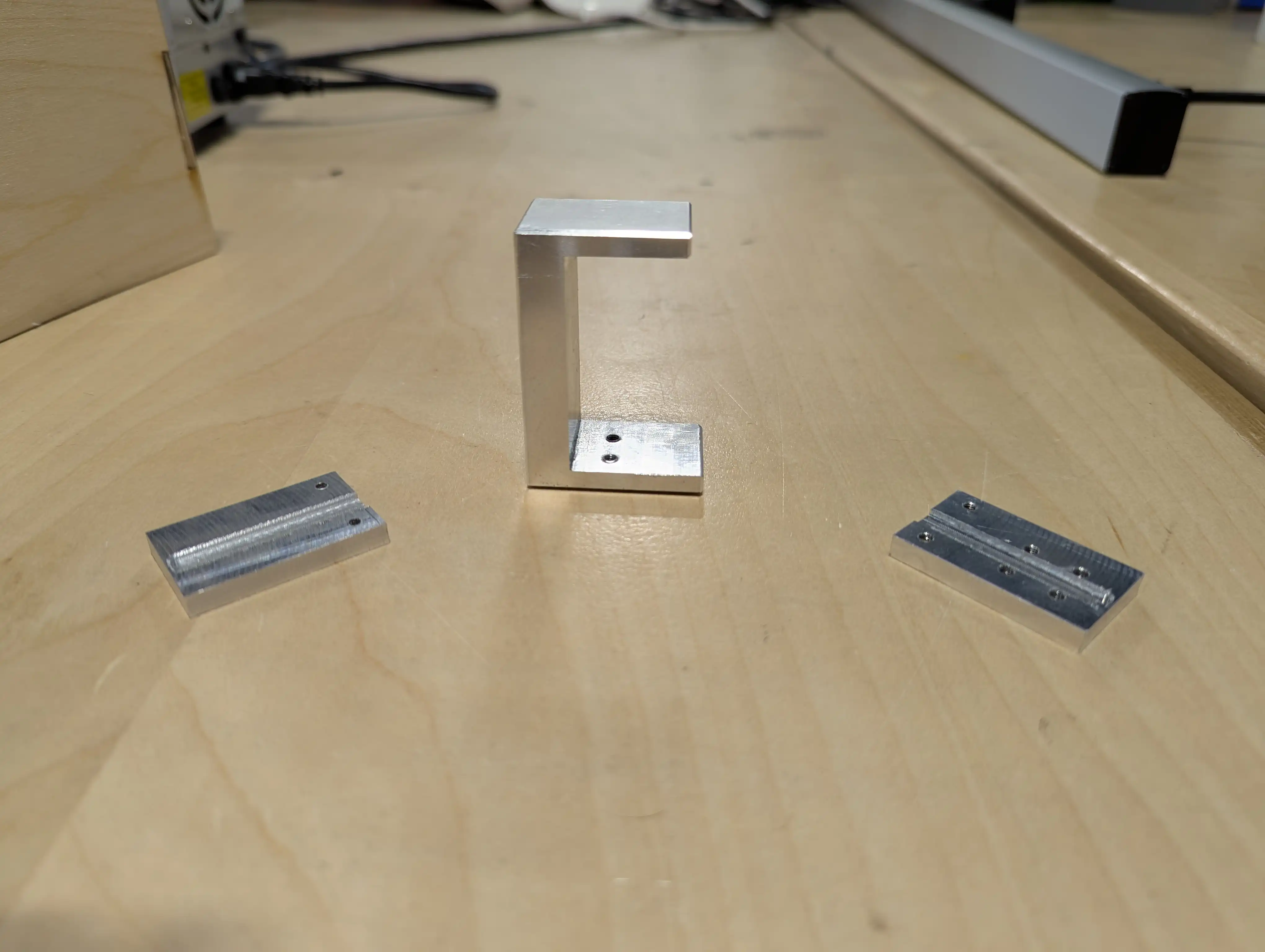

I spent the entirety of this week milling parts for the Band Saw Fence. So far, in the three days I’ve had this week, I’ve managed to mill one part per day.

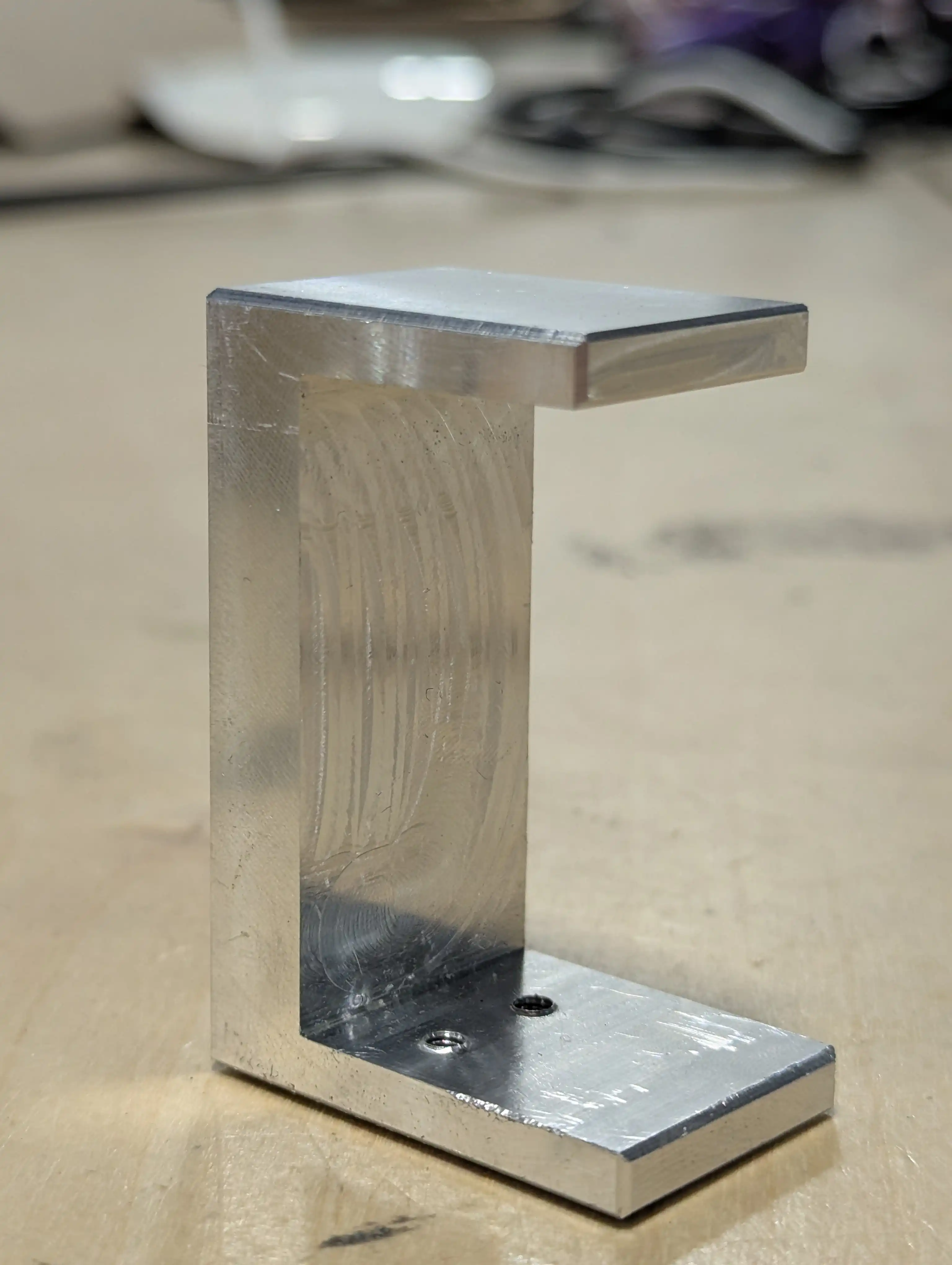

The static clamp was the first part I made. It fit perfectly on the band saw table, although I ended up breaking a tap while threading its holes. Because of that, one of the holes is useless, as it’s far more effort than it’s worth to extract the broken tap, so I guess that’s just part of it now.

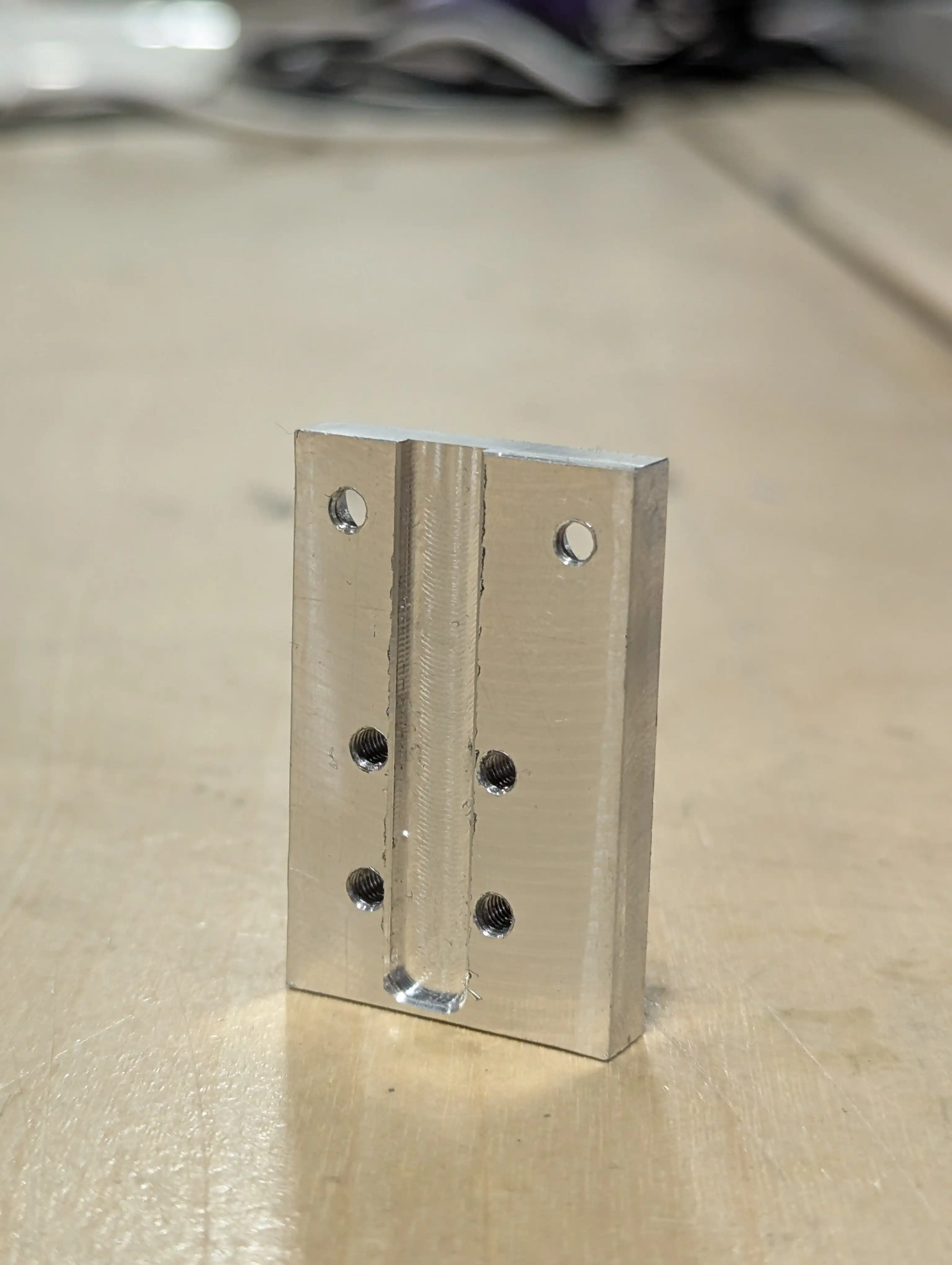

The top part of the moving clamp was the second part I made. It features a slot for the pusher to slide in, mounting holes to attach to the angle stock, and mounting holes to hold the three parts of the moving clamp together. The finish on the chamfer on the slot if really awful and I’m not sure why. I used the same 90° 1/4" bit that I used for the other chamfers and those came out fine. I guess super small chamfers just don’t turn out as good.

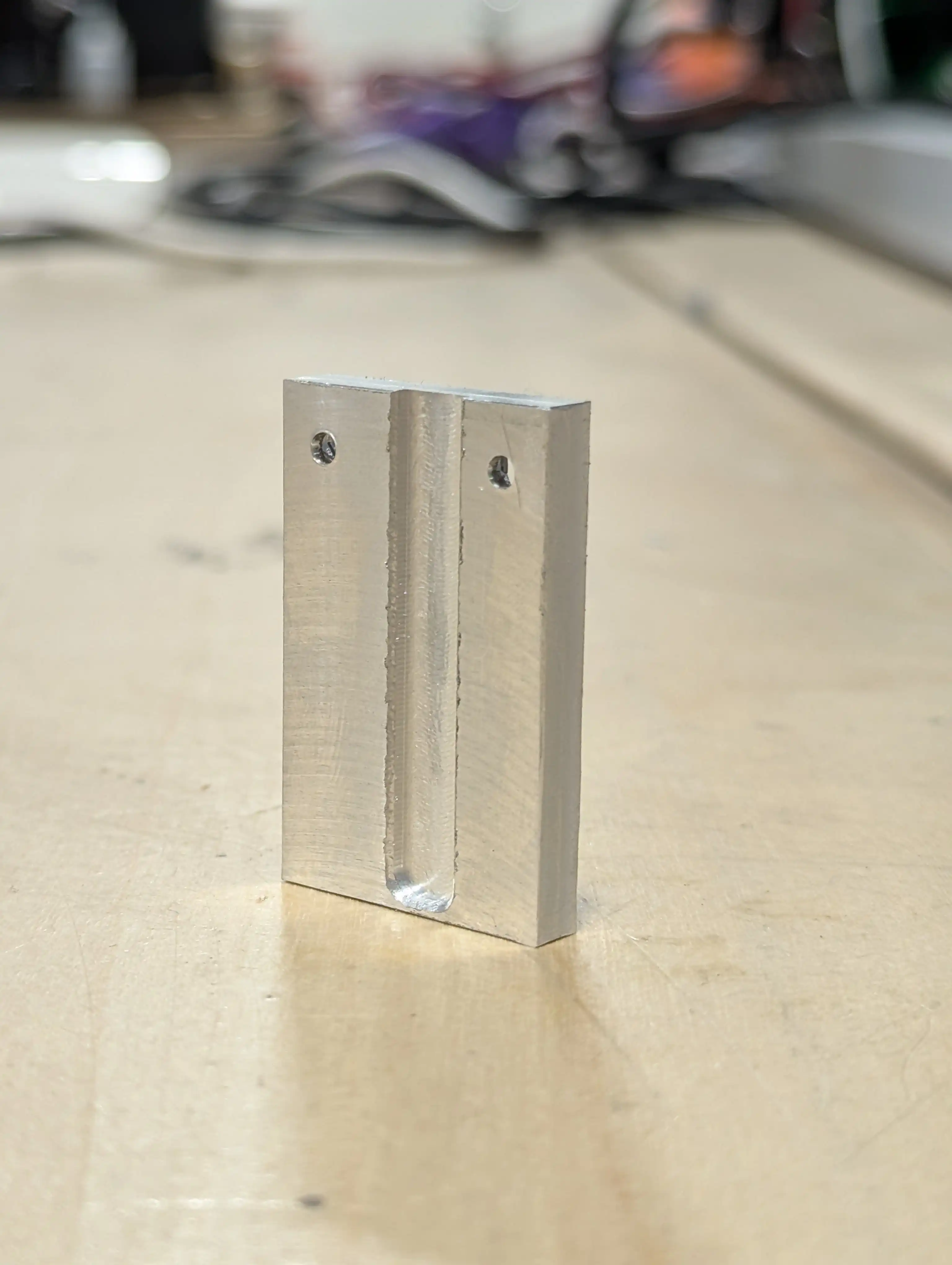

The bottom part of the moving clamp was the final part I made this week. It’s pretty similar to the top, but is mirrored and does not have the holes for attaching to the angle stock. It has the same issue with the slot chamfer.

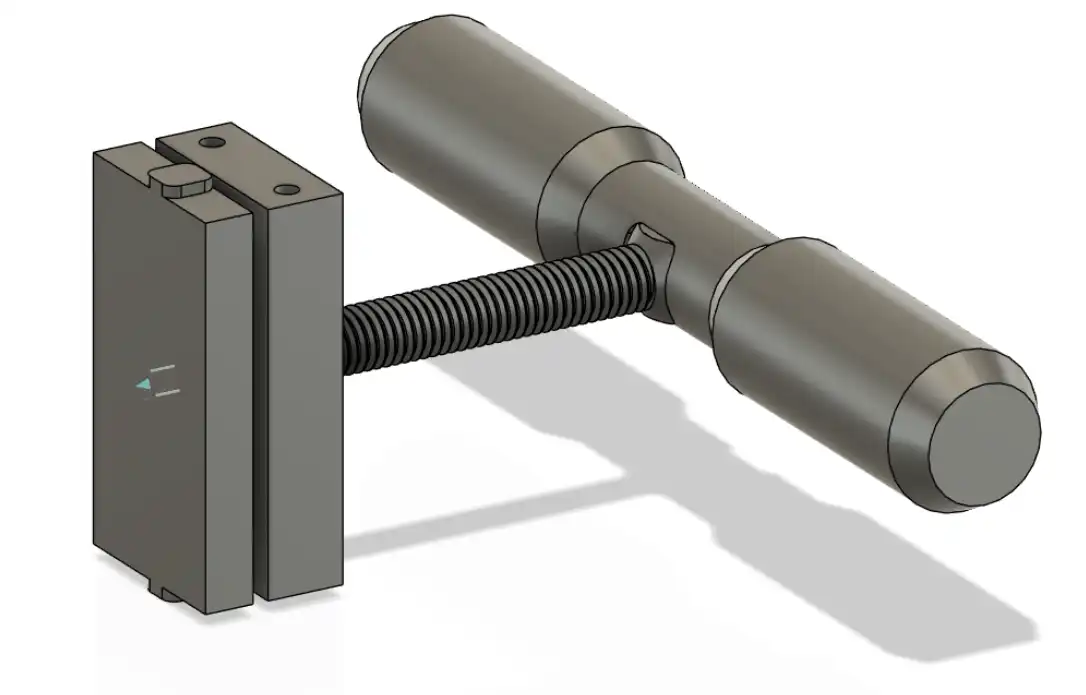

I have four more parts to make before I can call the Band Saw Fence complete, and although two will be easy, the two parts that make up the screw and handle will be far more complicated and will require both the mill and lathe to make.